Quality

QUALITY POLICY

“API METALS & FORGE(AMF) STRIVES TO CONTINUALLY IMPROVE AND DELIVER QUALITY PRODUCTS AT COMPETATIVE RATES ENHANCING CUSTOMER SATISFACTION THROUGH MANUFACTURING AND TIMELY DELIVERY WITH COMPLIANCE TO ISO 9001:2015 QUALITY MANAGEMENT SYSTEM THE PRINCIPLES OF THIS POLICY AND TO PROMOTE A POSITIVE CULTURE TO CREATE SAFE, HEALTHY AND ENVIRONMENT-FRIENDLY WORKPLACE. WE ARE ALSO COMMITTED TO BEING A ROLE MODEL ORGANISATION FOR OUR CUSTOMERS, SUPPLIERS, AND SOCIETY, WHILE CARRYING OUT OUR OBJECTIVES AND SATISFYING APPLICABLE COMPLIANCE REQUIREMENTS.”

Quality

Quality Control We have inculcated a culture of ‘Quality First’ throughout the organisation to ensure we can deliver to our promise & the part quality expected by our patrons & partners globally. A crucial part of any Forging Process is the In-Process Inspection methodology that adds an additional & crucial layer to the Quality Control Flow. This enables us to eliminate defects if any early in the production process & increase the efficiency of the whole operation. This also ensures a stringent Quality Control flow enabling us to achieve our 0% Rejection claim & promise policy. Our Team ensures that every part is precisely checked & we maintain traceability for every part that is dispatched from our facility

Specialty

- We are also a Leading Stockiest of Raw Material Bars with Special Material Grades like-Inconel 825,Incolonel 625,Monel 400,Hastealloy 276 & Titanium.

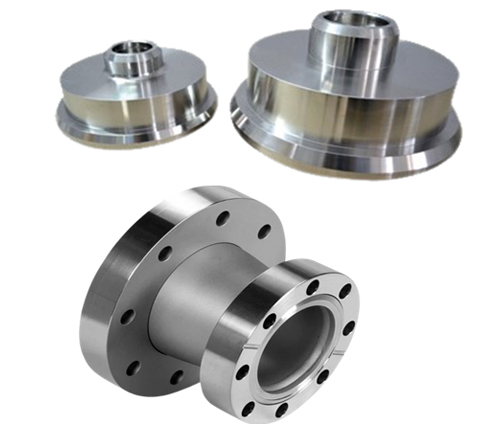

- We Manufacture High Quality Flanges,Thermowell,Flushing Rings and Fittings With Grades like-316/316L,304/304L,Duplex ,Super Duplex Inconel 825,Incolonel 625,Monel 400,Hastealloy 276 & Titanium

- All our Products conform to relevant material and dimensional specifications as per requirement and is supplied complete with material certificates to EN 10204/ 3.1.

Testing

Mechanical, Chemical & Metallographic Tests are carried out as under,

- Tensile, Impact & Hardness.

- Chemical analysis & PMI.

- Microstructure & ferrite content.

- Intergranular Corrosion Tests.

- Pitting Corrosion.

- Microstructure

- Tests by approved NABL accredited LABs.

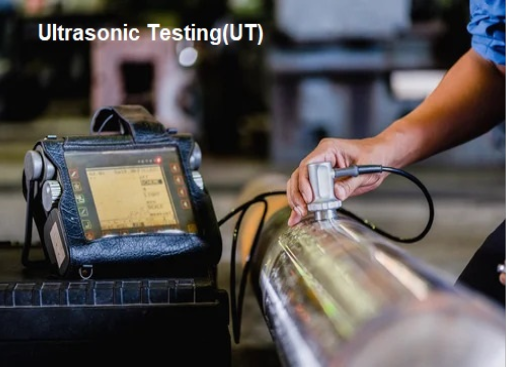

- Ultrasonic Testing.

- Magnetic Particle Testing (wet fluorescent and dry).

- Liquid Penetrant Testin

PACKING

Finished Flanges, Rings and other Forged components are applied with Rust Preventives as required and packed suitably for damage free transit along with necessary packing in Wooden cases or Pallets,Corraguated Sheets, Foams by. Road, Air & Sea Worthy.